Product features

1, All the moving parts of trim are stainless steel which is wearability and anti-corrosive.

2, For the steam cannot arrive to the valve seat hole by the water sealing that does not have steam losing and have highly effective energy saving.

3, It can¡¯t be destroyed and staved because of the Inverted bucket. It can bear water hammer and have a long usage circle.

4, It has air vent in the top of Inverted bucket. It has good performance to continuously vent air to lest Cold lag and aired up.

5, It can¡¯t influence by the back pressure and working well in the high back pressure.

6, It Works reliably, only has two movement parts (lever and Inverted bucket.) so that cannot form hinder.

7, The valve seat and disc are in the top of valve, the valve disc may cause the contamination passing in the on and pass. It has the good self- clean performance and no contamination.

Working principle

Inverted bucket steam trap using the density contrast of condensate water and steam to work. The internal structure is lever system connect with inverted bucket. The inverted bucket steam trap has a down facing inverted bucket as hydraulic sensor in order to overcome the steam pressure. When the device starts, in the pipeline appears the air and the low temperature condensate water. The Inverted bucket steam trap is full opening in this time, the condensate water rapidly discharges, the temperature rises quickly. The steam enters into inverted bucket which will produce upward buoyancy and the lever impetus valve core to close the valve. It has one hole in the inverted bucket which releases the air automatelly. When a little of steam discharges from the hole, the remainder steam will form condensate water. The inverted bucket loses the buoyancy and downward, the lever impetus the valve core to open the valve. When the steam enters into the inverted bucket, the valve closed again, circulate working, interrupted draining water.

Inverted bucket steam trap continuously drains water energy table (Kg/h)

| type |

880 |

881

881F

81 |

882

882F

82 |

883

883F

83 |

884

884F

84 |

815

815F

85 |

816816F |

|

0.5 |

240 |

420 |

800 |

1520 |

2500 |

3960 |

7190 |

| 1 |

280 |

470 |

930 |

1750 |

2950 |

4500 |

8600 |

| 2 |

230 |

460 |

930 |

1800 |

3020 |

4500 |

8150 |

| 4 |

280 |

410 |

920 |

2000 |

3050 |

4400 |

8800 |

| 6 |

280 |

380 |

800 |

1560 |

2600 |

4600 |

8000 |

| 8 |

310 |

420 |

900 |

1750 |

2950 |

4900 |

8850 |

| 10 |

260 |

365 |

660 |

1550 |

2550 |

4500 |

8450 |

| 12 |

200 |

380 |

720 |

1730 |

2880 |

4850 |

9000 |

| 15 |

230 |

335 |

560 |

1500 |

2500 |

3000 |

8400 |

| 17 |

250 |

350 |

600 |

1550 |

2600 |

3200 |

8650 |

| 21 |

-- |

240 |

860 |

1200 |

2200 |

3400 |

7200 |

| 25 |

250 |

900 |

1300 |

2400 |

2900 |

7800 |

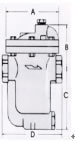

Fourth, structure and size880-815th, the side enters the side to leave, Filter, Outside dimension (mm)

|

tpye |

DN |

A |

B |

C |

D |

Maximum operating pressure kg/cm 2 |

| 880 |

1/2 '' 3/4 '' |

96 |

76 |

70 |

128 |

25 |

| 881 |

1/2 '' 3/4 '' 1 '' |

96 |

76 |

100 |

128 |

41 |

| 882 |

3/4 '' 1 '' |

145 |

94 |

137 |

170 |

25 |

| 883 |

1 '' 1 1/4'' |

180 |

120 |

193 |

202 |

25 |

| 884 |

1 1/4' 1 1/2'' |

203 |

150 |

212 |

232 |

25 |

| 815 |

1 1/2'' 2 '' |

220 |

148 |

248 |

250 |

25 |

881F-886F¡¢Flange ¡¢Filter¡¢ Outside dimension£¨mm£©

|

type |

DN |

A |

B |

C |

D |

Maximum operating pressure kg/cm 2 |

| 881F |

15. 20 .25 |

96 |

76 |

100 |

170 |

25 |

| 882F |

20 .25 |

145 |

94 |

137 |

210 |

41 |

| 883F |

25 .32 |

180 |

121 |

193 |

270 |

25 |

| 884F |

32 .40 |

203 |

150 |

212 |

320 |

25 |

| 815F |

40 .50 |

220 |

148 |

248 |

320 |

25 |

| 816F |

65 .80 |

265 |

489 |

310 |

400 |

25 |

81-86 under enters the type exterior dimensional drawing (mm))

|

type |

DN |

A |

B |

Maximum operating pressure kg/cm 2 |

| 81 |

1/2 '' |

108 |

162 |

25 |

| 82 |

3/4 '' 1 |

133 |

203 |

25 |

| 83 |

1 '' |

162 |

273 |

25 |

| 84 |

1 1/4'' |

184 |

314 |

25 |

| 85 |

1 1/2'' |

216 |

380 |

25 |

| 86 |

2 '' |

260 |

432 |

25 |

The essential to order

1. According the maximum steam consuming capacity multiply the selected magnification of steam equipment (2-3 times) in order to choose the displacement of trap for the maximum condensate water capacity

2.The maximum differential pressure of trap (The front operating pressure minus the back pressure of valve ) should be noted if has back pressure.

3.The maximum operating temperature of the trap

4.The operating condition of the trap

5.Ends connection6.Body material